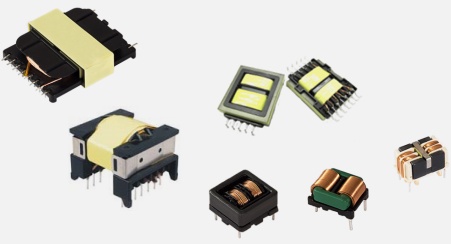

1.The miniaturization and flattening of AC/DC.DC/DC can adapt to smaller volume, higher current output, and higher power density and efficiency requirements.

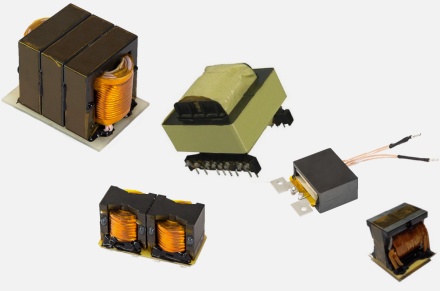

2.High-power PFC and EMI products use a flat wire vertical winding process to improve consistency and utilize space to greatly improve heat dissipation efficiency.

Trends and solutions for automation products.

TV series product package, can adapt to the needs of different sizes of TV flat.

Increase the power density and AE value under the premise of the same size.

Ultra-thin transformers can be adapted to the customer's height requirements. Widely used in TV and other fields.

For the lighting field HID, BALLAST, LED, etc. have a deep understanding and accumulated a lot of research and development and production experience.

For the Charger products, interact with the customer RD to realize the automation design and mass production process. EMI products, many specifications and models, can meet the needs of customer selection.

Non-skeleton and multi-core core stack for high current. Greatly improve the utilization efficiency and reduce the occupied space. At the same time, LITZ and copper foil can be used. It can adapt to the requirements of different lines of customers and increase the skin effect. Make the application rational.

With insulation system for medical power supply, it can meet customer safety requirements. Make the corresponding customization.

High reliability requirements for high power supplies in special applications, and immunity to electromagnetic interference. Power frequency transformers and reactors are extremely optional.